Fan coil selection, installation and precautions

China has the following items in the fan coil test indicators: air volume, cooling capacity, heat supply, unit fan power cooling capacity, water resistance, A sound level noise, condensation, condensate treatment, motor winding temperature rise, Thermal insulation resistance, leakage current, grounding resistance and other indicators. However, we evaluate the quality of a fan coil in the project mainly depends on its air volume, cooling capacity, noise and power consumption.

Usually when choosing a fan coil, many people think that the coil technology has already passed, and each manufacturer's products are similar, so they are often only considered from the price. However, in terms of power consumption, the difference between the maximum power consumption and the minimum power consumption of the same product is more than 20W. The following will talk about the selection of fan coils, matters to be aware of, the impact of parameter changes on performance and installation principles.

First, how to choose the fan coil

Fan coil selection

Fan coils have two main parameters: cooling (heat) and air supply, so there are two options:

First, according to the room circulation air volume selection: the product of the room area, floor height (after the ceiling) and the number of room ventilation times is the circulating air volume of the room. The fan coil type can be determined by using the circulating air volume corresponding to the high and medium speed air volume of the fan coil.

Second, according to the cooling load required by the room: according to the unit area load and room area, the cold load value required by the room can be obtained, and the fan coil type can be determined by the cooling capacity of the fan coil corresponding to the room cooling load.

Second, the fan coil selection considerations

1, cooling capacity

Insufficient cooling is one of the most common complaints from users. The main reason for this problem is that many companies do not have their own testing methods. The parameters on the samples are also copied from other manufacturers. The thermal performance of the coils produced by them is poor (mainly by fin form, tube quality, production). Process etc.). Therefore, it is recommended to pay attention to the testing facilities and means of the manufacturer when conducting project inspections. It is difficult to imagine that a manufacturer without its own testing device can produce good products.

2, the amount of air

How to consider the volume of the coil is a problem. Most manufacturers in the domestic market have only one type of three-row tube, and some manufacturers provide two-row tube coils. In fact, it is more advantageous to select a two-row coil for most civil building air conditioning systems (except for high humidity applications). This is because the product of the two-row tube has a large air volume under the same cooling capacity, which will increase the number of air exchanges in the air-conditioned room, which is beneficial to improve the accuracy and comfort of the air-conditioning. Under the same amount of cold, using a small temperature difference and a large amount of air to deliver air, it will achieve better air conditioning than a large temperature difference and a small air volume.

3, external residual pressure

At present, the national standard stipulates that the air volume, cooling capacity and noise of the fan coil are tested under the condition that the static pressure outside the machine is zero. In actual use, the coil outlet is often connected with a small duct and air outlet louver, and some projects also have a return air box. Therefore, in actual use, the actual air volume of the coil is less than the nominal air volume. The consequence is that the room air volume is reduced, the air supply temperature difference is increased, and the comfort of the air conditioner is reduced. In order to avoid this situation, some designers select the mid-range air volume according to the coil when selecting the type to avoid the shortage of air volume, but increase the initial investment of the project. Therefore, it is recommended that in the case that the domestic test standards have not been changed, the coils should be selected with a residual pressure (generally 10-15 Pa).

4, noise

This is a place where the gap between domestic products and foreign products is currently large, and it is also a point that the coil is being complained about due to quality problems. The cause of this problem is mostly the unreasonable configuration and matching of the motor and fan in the coil. Another reason is that the quality management of the manufacturer is not strict, the responsibility of the assembler is not strong, and the product quality is unstable. Therefore, when we inspect a manufacturer's products, we should consult the noise detection report of the product (must be the products we are going to order) issued by the national authority quality inspection department. For the large-scale project, the sample should be sent on site. Relevant quality inspection department inspection.

Third, the impact of parameter changes on performance

Effect of parameter changes on performance

1. The fan coil has a certain air volume, the water supply temperature is constant, and when the water supply volume changes, the cooling capacity changes with the change of the water supply quantity. According to the performance statistics of some fan coil products, when the water supply temperature is reduced by 80%, the water supply is reduced by 80%. The amount is about 92% of the original, indicating that the impact on the cooling capacity is slow when the water supply changes.

2. The temperature of the water supply back to the fan coil is constant. When the water supply temperature rises, the cooling capacity decreases. According to statistics, when the water supply temperature rises by 1 degree, the cooling capacity is reduced by 10%. The higher the water supply temperature, the greater the reduction and the dehumidification capacity decreases.

3. The water supply condition is certain. When the air volume of the fan coil is changed, the difference between the cooling capacity and the air conditioning treatment varies. Generally, the cooling capacity is reduced, the enthalpy difference is increased, and the power consumption per unit cooling capacity level is not changed much.

4. When the inlet and outlet water temperature of the fan coil increases, the water volume decreases, and the heat coefficient of the heat exchange coil decreases. In addition, the heat transfer temperature difference has also changed. Therefore, the cooling capacity of the fan coil decreases as the water supply temperature increases. According to statistics, when the water supply temperature is 7 degrees and the return water temperature is increased from 5 degrees to 7 degrees, the cooling capacity is reduced by 17%.

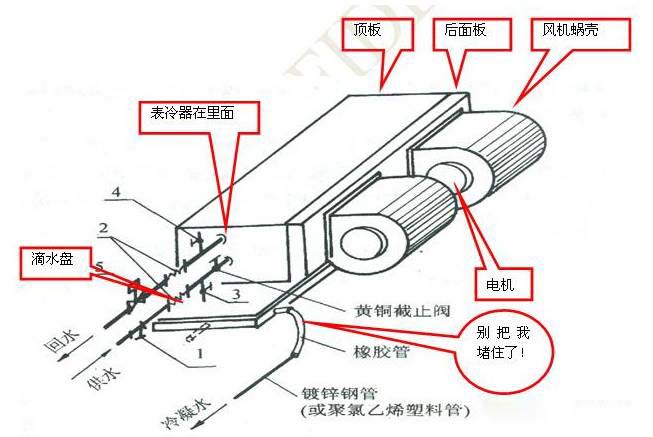

Fourth, the fan coil installation principle

Fan coil installation principle

1) When installing the wall-mounted vertical unit, the energized side is required to be slightly higher than the water-passing side to facilitate the discharge of condensed water.

2) When installing the unit, the unit's condensate pipe should be kept at a certain slope (usually 5 degrees) to facilitate the discharge of condensate.

3), the unit inlet and outlet pipes should be added to the insulation house to avoid condensed water during summer use.

4) The unit condensate drain hose should not be flattened and bent to ensure the smooth discharge of condensate.

5) During the installation, heat exchanger fins and elbows should be protected from backlash or leakage.

6) When installing the horizontal unit, the boom and expansion bolt should be properly selected.

7) When the horizontal mounted unit is installed in the inlet and outlet pipes, the inlet and outlet pipes can be taken out of the machine on the ground, and then connected to the pipe after lifting; or the panel and the condensate pan can be removed after lifting. Then connect and then keep the water pipe to prevent condensation.

8) When the vertical mounted unit is installed in the inlet and outlet pipes, the tuyere panel of the unit can be removed for installation; and the water pipes are insulated to prevent condensed water from being generated.

9) The unit return pipe is equipped with a manual bleed valve. Before the operation, the bleed valve should be opened. After the air in the coil and the pipeline is drained, the bleed valve is closed.

10) Prepare a grounding bolt on the unit's housing for connection to the protective earthing system during installation.

11), the rated voltage of the unit power supply is (220±220x10%) V, 50Hz. The line connection is connected according to the “electrical connection circuit diagram” provided by the manufacturer. The color of the connecting wire is required to be consistent with the wiring label.

12) Because the size of the air inlet of the wind coil air conditioner produced by each manufacturer is not the same, care should be taken not to make mistakes when making the return air grille and the air supply port.

13) The control panel of the unit with temperature controller should have a winter and summer transfer switch, which is placed in summer in summer and winter in winter.

14) The insulation material of the unit shall not be damaged during installation. If it is detached, it shall be re-adhered. At the same time, the connection with the air supply duct and the tuyere shall be tightly connected.